Sigma

Sigma Sigma

Sigma

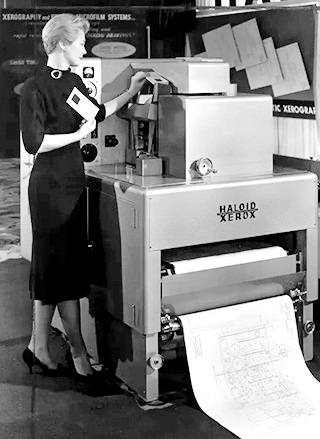

In 1974, I was hired by Xerox as a Technical Representative ‐ or Tech Rep as we were known. My first assignment was to care for two legendary machines: the Xerox 2400 and 3600 duplicators.

The 2400, introduced in 1964, had been a monumental leap forward for Xerox. It took four years and about $40 million to develop, tightening tolerances down to an incredible 17 millionths of an inch. It was a major departure from the earlier 914 ‐ based not just on empirical tinkering but on solid, practical engineering. Internally, the project had once been called Project Bunny, because of its "reproduction" rate, then Phoenix, and finally just "150." Originally, it was a revenue disappointment. However, by 1968, the 2400 family turned things around. It accounted for 10% more copies than all earlier Xerox products combined.

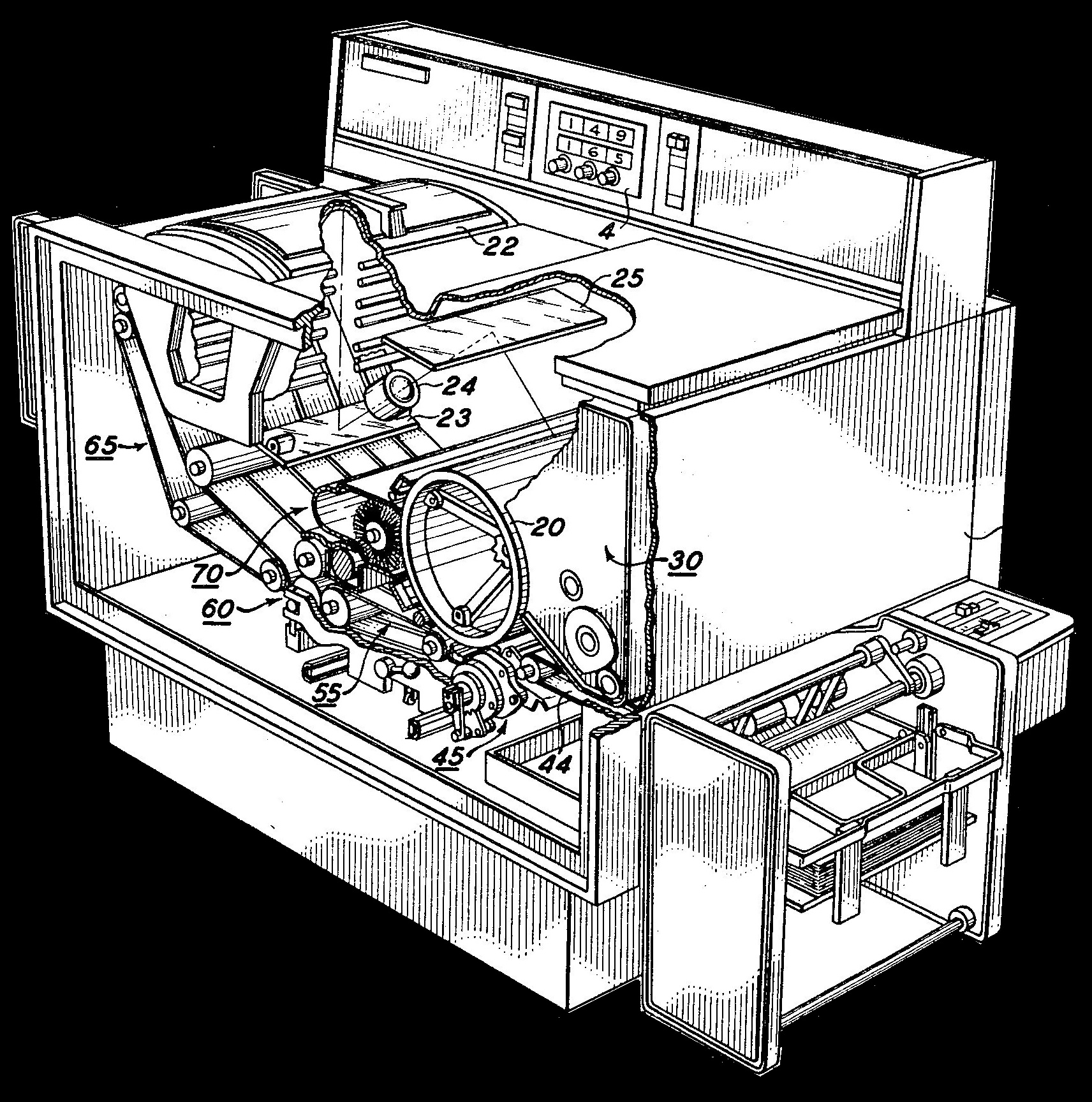

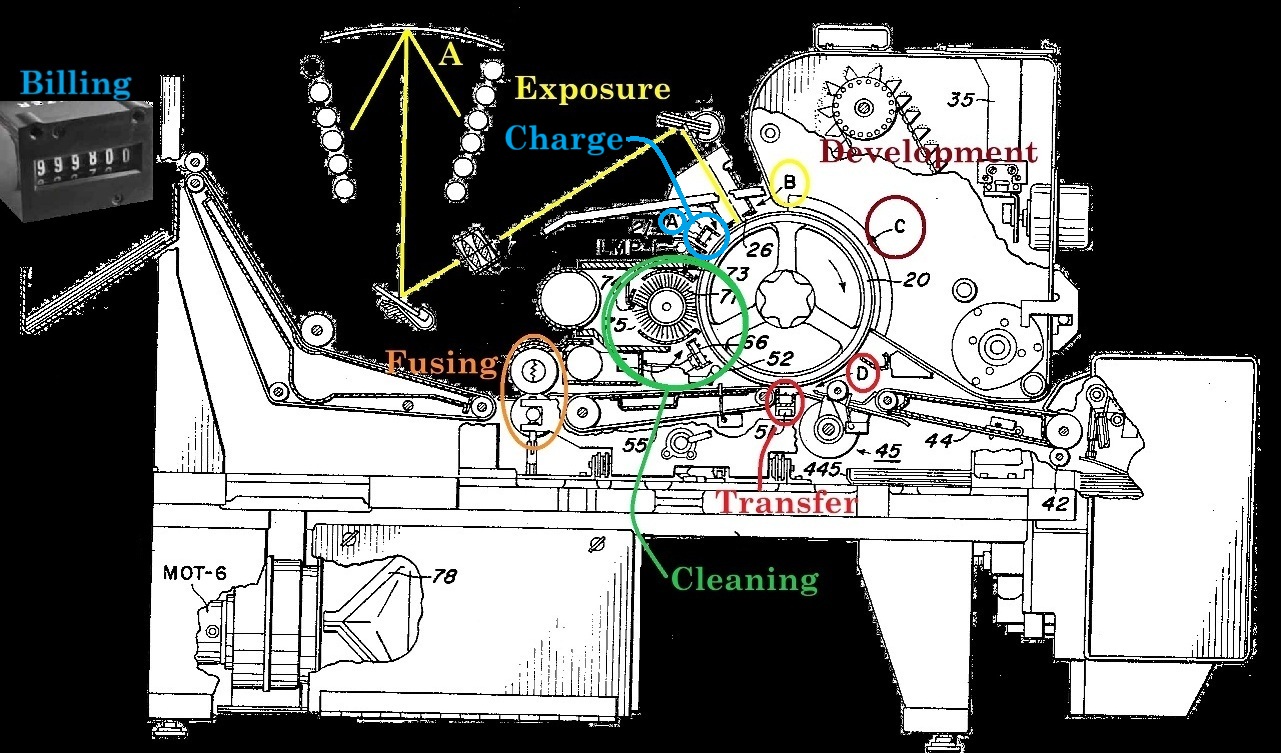

These machines were big, noisy, and mechanically complex beasts. Belts, pulleys, rotating cam systems, main chains, clutches, and solenoids filled their insides. System timing was mechanical, driven by rotating cams. The electronics were basic ‐ mostly relay logic. They used the classic xerographic process: charge, expose, develop, transfer, fuse, and clean. Last but definitely not least, bill. At that time, Xerox did not sell copiers, but copies. It made Xerox the success it had become when I arrived. But now the business model was getting long in the tooth and market forces were starting to force a rethink on the whole concept.

Billing plans had gotten so varied and complex that most machines had four or more side by side counting meters. The most complex electronics in these machines were called the "programmer." It is where the user would dial in the amount of copies desired. The programmer would count the copies as made and put the machine into its shutdown and stop mode when the number was reached. As each copy was made the leftmost meter would count every copy, but the rest would stop at some point depending on the count. The goal was to get the user to make lots of long runs and not so many single copies.

On these machines one of our most important tools was the vacuum cleaner but not any vacuum. It had to be a brushless vacuum, because a spark from a regular one could cause a toner explosion. Toner management ‐ keeping toner in the right places and out of the wrong ones ‐ was an everyday battle. The machines ran so hard that about 20% of the toner used ended up trapped in a vacuum box with a huge filter bag.

Cleaning the photoreceptor after each copy was a whole system of its own: a rotating cleaning brush, a discharge corotron, and a lamp. The copy paper was separated from the drum with a clever "puff" of air ‐ if the timing was wrong, the machine would stop with a dreaded "mispuff" error. (Machines that didn't use air puffs used stripper fingers to peel the paper off.)

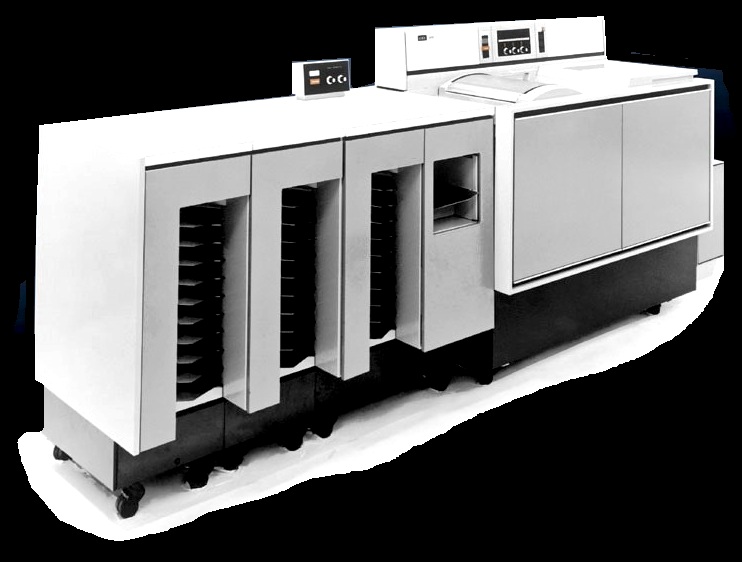

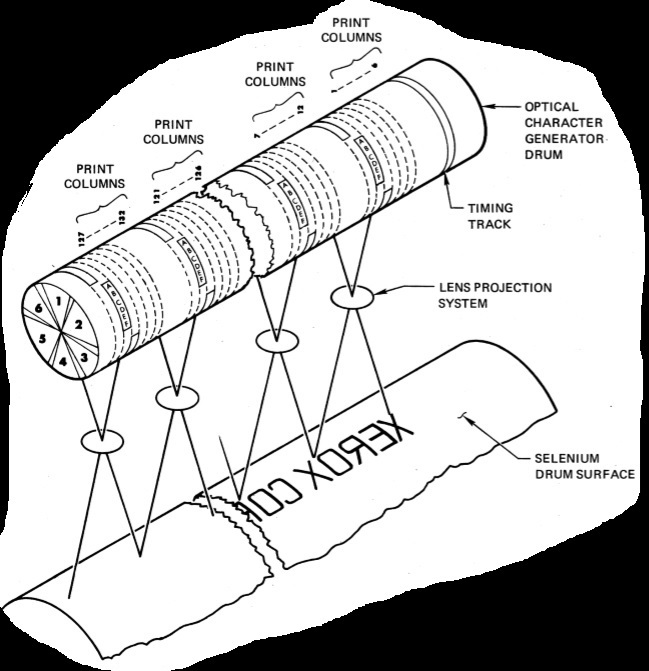

Xerox was very good at finding new uses for 2400 frames. Remember that at this time almost all the machines were rentals. When a customer would move on to a new machine, from Xerox or a competitor, it got the machine back. It could then take the base frame and turn it into something else. Frames that were 2400s could become 3600s, 7000s, or this one above. The 1200. It could take data from tape or directly from mainframes and produce plain paper printouts.

Some of my machines ran close to a million copies a month. They only stopped for paper reloads, jams, or maintenance ‐ and they needed frequent attention. These duplicators were tough ‐ tanks, really ‐ but they required constant babysitting.

Later on, I was trained on the 4000/4500 series. At first glance, these machines seemed familiar: they made 40 copies per minute, like the 2400. But inside, everything was different.

The 4000 family introduced digital logic in place of mechanical relays. The cascade development system was improved so it could handle solid areas better. Instead of a cleaning brush, it used a doctor blade ‐ a flat rubber blade that scraped toner off the drum.

The 4000 series also had a toner recovery system using an auger and bead chain to move recovered toner back to the developer unit. Unfortunately, the idea didn't work well. Paper dust mixed in with the toner, fouling the recovery system, and eventually the doctor blade would fail from all the accumulated dust.

Compared to the duplicators, the 4000 series machines were smaller, more delicate, and less forgiving. Working on them was harder ‐ the systems were packed tightly together, and fixing one system often meant dismantling several others to get to it. Despite running at the same 40 pages per minute as the 2400, they weren't built for the same punishment. The duplicators were ironclad workhorses; the 4000s were precise instruments that needed a gentler touch.

Yet, the 4000 family had one major innovation: automatic two‐sided copying ‐ a first for Xerox.

The last machine I trained on was the 5400. While it shared the same styling and footprint as the 4500 in the 4000 family, (both had built&dash'in sorters) under the hood it was completely different. The 5400 was the first copier I worked on that had a microcontroller at the heart of its control system.

This meant it could do things no previous copier I worked on could, like automatic job recovery after a paper jam. On older machines, it was up to the operator to figure out where they were in a copy run ‐ not anymore. The 5400 brought back the cleaning brush instead of a "doctor" blade and got rid of the troublesome toner recovery system entirely. It also featured second‐generation brush development. The controller let us test sensors, switches, buttons, and lamps individually. This was a huge leap in diagnostic capability.

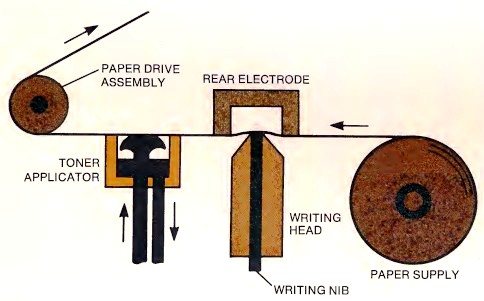

I also worked on Versatec printers and plotters. Versatec was a company started in 1969, which was bought by Xerox in 1975. To me this was always an interesting purchase. What sprung Haloid up into what became Xerox was all based on the whole "dry writing" approach using plain paper. Versatec's tech used a wet method. It involved special electrographic paper, liquid toner, and a clear dispersant developer solution.

Voltage was applied to an array of densely spaced writing nibs embedded in a stationary writing head. The nibs selectively created minute electrostatically charged dots on the paper as it passed over the writing head. The paper was then exposed to liquid toner to produce permanent, visible text or images.

The "high tech" of the day allowed resolutions of 160 and 200 dots per inch, a 16 x 16 matrix, and dual array density. It had a proprietary Versatec Roman font, which was claimed to further enhance readability. When it was not in a regular printing mode, but in a plotting application, Versatec had software, Versaplot, that offered four choices in line thickness and a "Tone" subroutine that shaded bounded areas with a wide selection of dot patterns. Also in tune with the day's technology it could accept data at up to 9600 BPS. One thing you could say about the machine that was for its size it was extremely quiet.

Service life wasn't without surprises. One day, I was called to a small office where the entire staff were waiting outside. The smell inside the building was unbearable. When I got to the machine, I found out why: a rat had gotten across one of the plunger relays that supplied 240V to the main motor.

The rat didn't survive ‐ it was still slowly sizzling when I arrived and disconnected power. The body had created a short circuit that backfed voltage into parts of the machine where it was never intended to go. I had to replace several components, including the relay itself. Usually, we could rebuild relays on-site, but the smell alone convinced me to remove and discard the entire thing. I bagged it carefully, brought it back to the depot, and they decided to toss it into the trash.

After that experience, I learned to always check for signs of rodents inside machines ‐ chewed wires, droppings, or worse. Rodent visits to office machines were more common than many wanted to admit. This happened often in quiet offices after hours.

My six years at Xerox were hands‐on, dirty, technical, and often unpredictable. I saw the tail end of industrial mechanical copiers, the rise of digital logic machines, and the first stirrings of microcontroller intelligence ‐ all while crawling inside machines the size of refrigerators, battling toner, and occasionally, rats.

It was a front-row seat to a company and an industry evolving at high speed ‐ from mechanical engineering marvels to smart, electronic systems that would eventually help lay the groundwork for the connected, digital office of the future.